Materials play a major role in our digital society. Predicting and avoiding their failure is an important endeavour for scientists. Failure in materials is often caused by the action of degradation mechanisms which can be understood as extrinsic or intrinsic forces that modify their initial characteristics, therefore in the worst case scenario, inducing its collapse when in operation.

The main aim of our research team is to raise the world’s awareness regarding materials deterioration in extreme environments. Through fundamental metallurgy research, we aim at unravelling the physical mechanisms by which such deterioration occur and how it can be prevented.

Our definition of “Extreme Environment“

Environmental driving forces capable of transforming materials by changing their thermodynamic equilibrium (or non-equilibrium) state.

−e.g. Irradiation, corrosion, high temperature, plasmas…

Ref.: D.S.R. Coradini, M.A. Tunes et al. npj Materials Degradation 4, 33, 2020 (doi.org/10.1038/s41529-020-00137-2)

Our definition of “Materials Degradation“

Modification of both initial thermodynamic state and properties of material caused by the action of external forces in an (extreme) environment.

−e.g. Oxidation, embrittlement, amorphisation, phase transformations…

See for example: M.A. Tunes et al. Materialia 7, 100408, 2019 (https://doi.org/10.1016/j.mtla.2019.100408).

Importance of basic research in metallurgy

The modifications that materials may experience in their properties and/or microstructures when exposed to an extreme environment is one of the major topics of research in our group at a fundamental level. Here, understanding the basic concepts of metallurgy and how they apply in equilibrium and non-equilibrium conditions is of paramount importance.

Materials Defects: Displacement and Impurity Damage

Dislocations are defects in the atomic arrangement of crystalline materials. Our group investigates their formation and interaction with microstructural sites, as these defects are linked to degradation mechanisms like embrittlement.

Video: Titanium nitride/Aluminium interface: Formation of dislocation loops in aluminium under energetic particle irradiation.

Phase transformations

An austenitic stainless steel (AISI-348) under irradiation can experience formation of secondary phases such as the Cr-rich alpha-prime phase. We have demonstrated that the system converges to equilibrium due to the effects of irradiation!

Video: M.A. Tunes et al. Acta Materialia 179, 360-371, 2019 (doi.org/10.1016/j.actamat.2019.08.041).

Similarly, energetic particle irradiation at a temperature can drive precipitation of MC and M23C6 phases into the austenite matrix of the AISI-348.

This is an example of accelerated aging induced by the action of an external force.

Video: M.A. Tunes et al. Materialia 7, 100408, 2019

(doi.org/10.1016/j.mtla.2019.100408).

In some situations, inert gas bubbles – formed through transmutation reactions in nuclear reactors – can also promote accelerated aging in austenitic stainless steels under irradiation.

Video: I. Oyarzabal, M.A. Tunes et al. J. of Nuclear Materials 541, 152414, 2020

(doi.org/10.1016/j.jnucmat.2020.152414)

Ultra-fast solidification rates

This is a very nice experiment that my friend Dipl.-Ing. Dr. mont. Philip Dumitraschkewitz is currently leading the efforts and the project at our university.

He is investigating the solidification of alloys by melting, but using micro-electro-mechanical systems (MEMS) technology. Using a high-temperature MEMS TEM holder, he is able to study how the microstructure evolves and transforms during cooling rates in the order of millions of Kelvin per second!

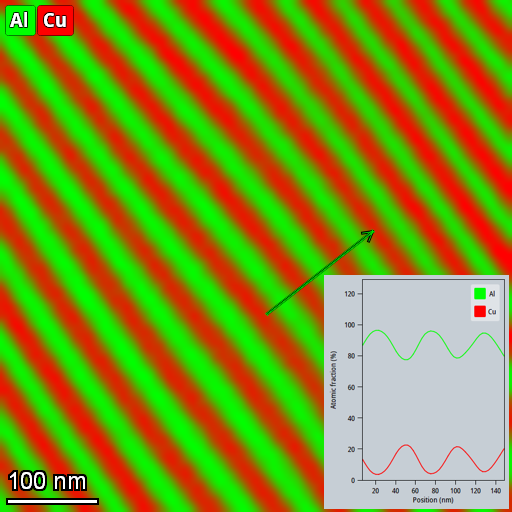

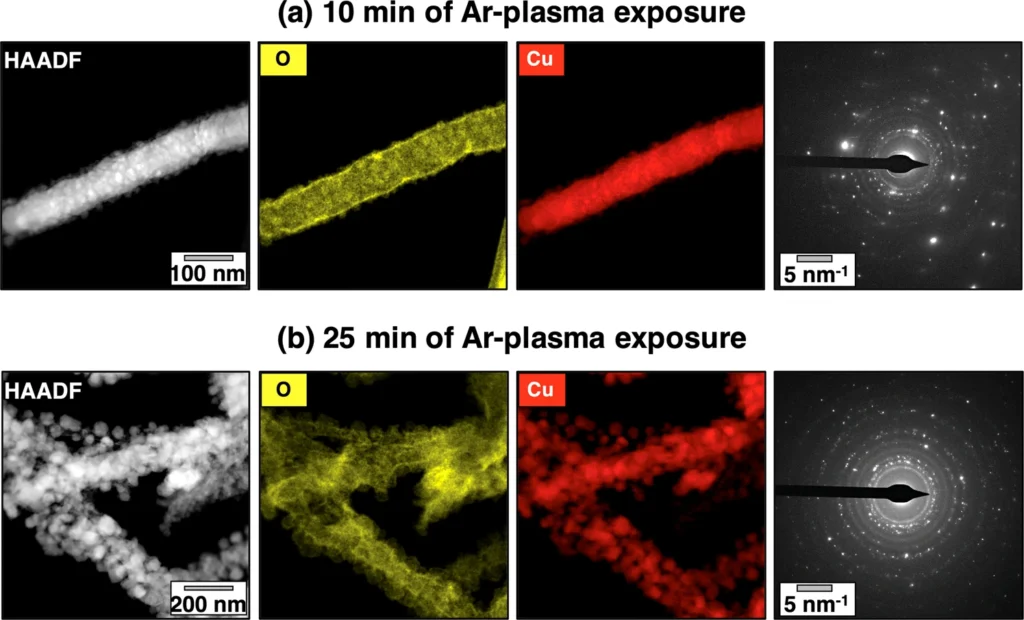

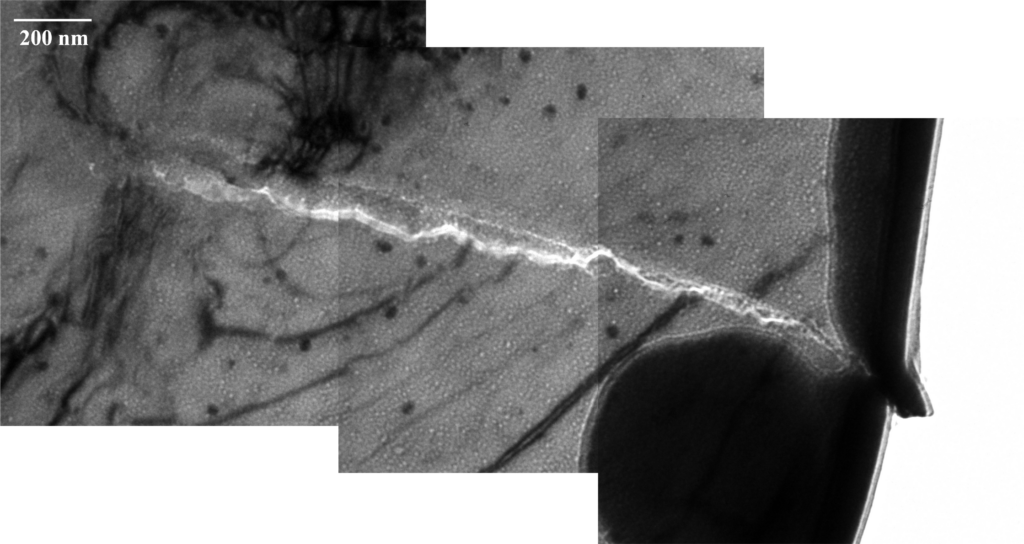

The experiment on the right was performed on 16/07/2020 when several members of our group were in the TEM room, anxiously waiting to see if the rapid solidification idea was going to work. Everyone was amazed when the eutectic AlCu solidified into a beautiful lamellar nanostructure!

It was a happy day for science!

Paper: P. Dumitraschkewitz, M.A. Tunes et al. Acta Materialia 239, 118225, 2022 (doi.org/10.1016/j.actamat.2022.118225)