Hydrogen Damage and Hydrogen Embrittlement

The formation of hydrogen-rich precipitates in metallic alloy matrices causes severe materials’ embrittlement, accelerating failure rates.

In response to the growing demand for renewable energy, we have an active research line into the realm of hydrogen-based materials. In addition, our investigations into the degradation effects of monoatomic hydrogen in materials have been crucial for identifying potential challenges and devising mitigation strategies. We are currently seeking funding for our projects HYDRONVISION and HYDROINGENIUS which are ambitious basic science initiatives for the next revolution in metallurgy and materials sciences!

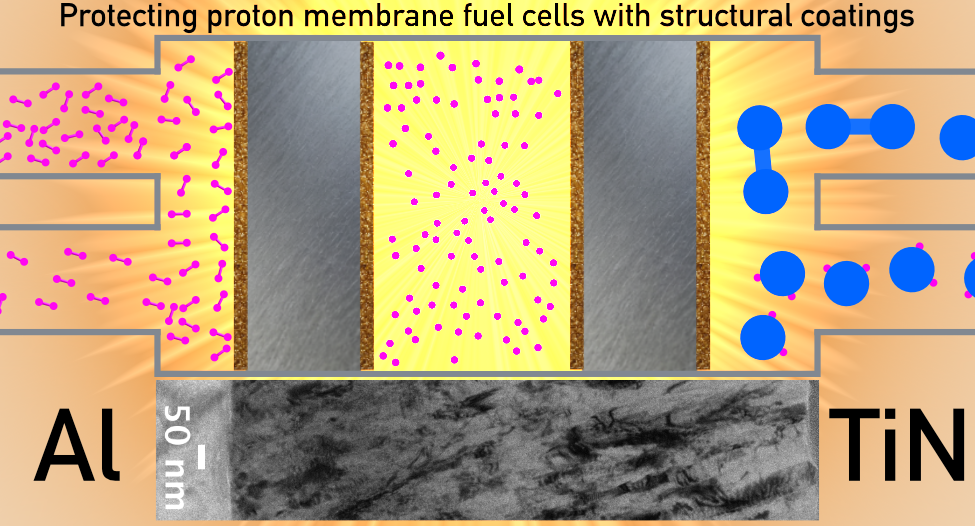

Water Electrolyzers and Fuel Cells

Hydrogen energy presents a promising and necessary solution to address global warming. For large-scale hydrogen production and storage, Water Electrolyzers (WEs) and Fuel Cells (FCs) are key technologies. Among these, Proton Exchange Membrane Fuel Cells (PEMFCs) are particularly efficient. However, for PEMFC devices to meet the US Department of Energy’s 2025 operational targets, the bipolar plates — a crucial component — must enhance both corrosion resistance and electrical conductivity, especially in harsh and acidic environments. Our research focuses on applying Physical Vapor Deposition (PVD) coatings to metallic plates to improve these properties, contributing to global warming mitigation efforts.

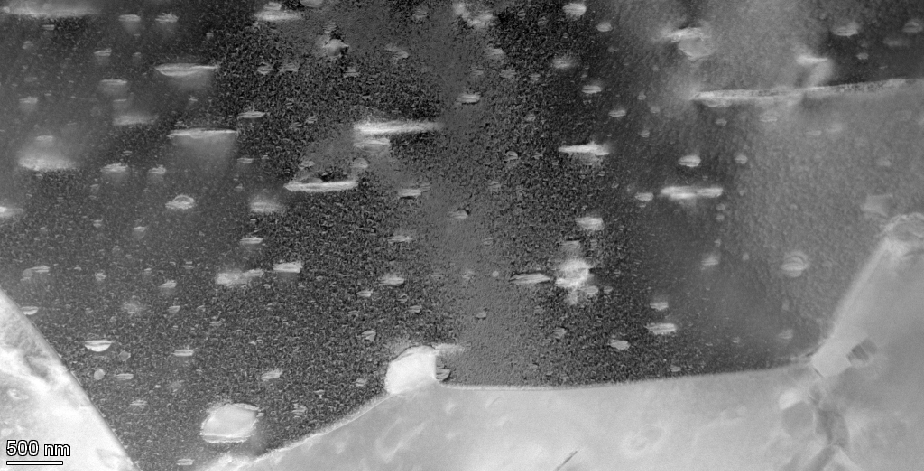

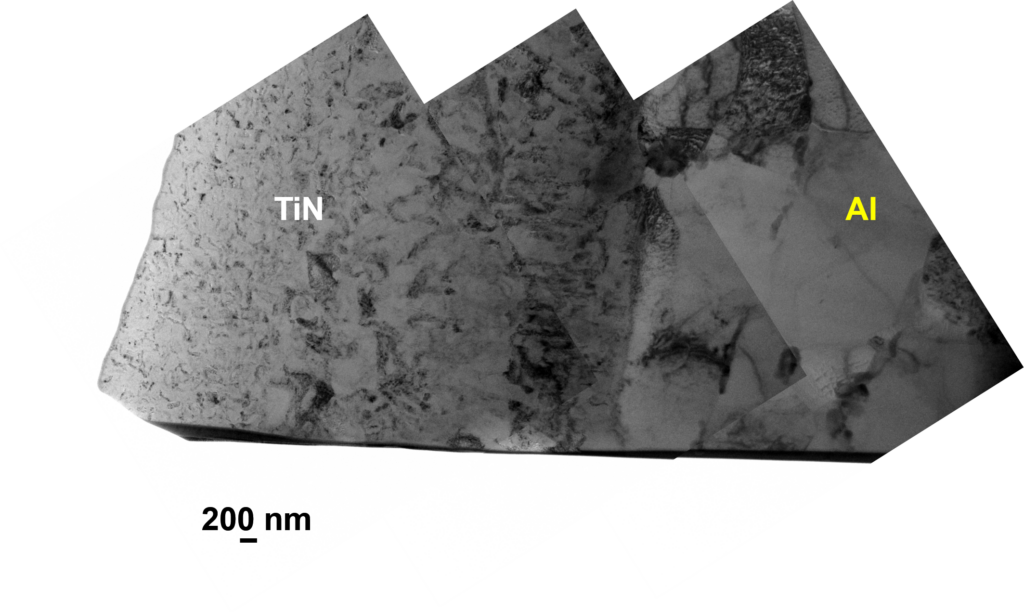

Our research group is investigating ways to make aluminium a viable candidate for use in fuel cells.

We are investigating new strategies to increase the corrosion resistance of aluminium in simulated fuel cell environments. One current strategy is the deposition of thin films on aluminium alloys.